Established in 2007 as part of the Naylor Group, Naylor Specialist Plastics Ltd. is well known for the manufacture of extruded thermoplastic profiles and specialist plastic tubular products across a number of different business to business and consumer sectors, including retail and construction.

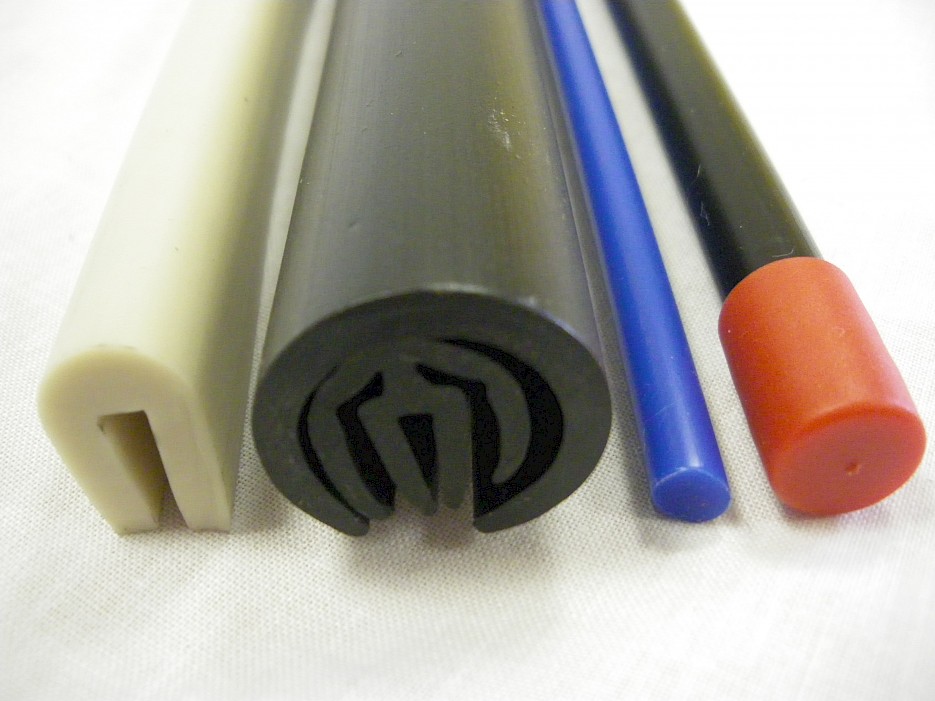

Although we provide an extensive range of plastic tubes and profiles ‘off the peg’, because of continuous investment in our manufacturing capabilities, we can also offer our customers bespoke plastic tubes or profiles that may not be easily available commercially.

Through continued investment in the latest equipment, we have the manufacturing capability and versatility to produce any size of plastic tube from 2mm to 315mm here in the UK, from our sites in Wombwell and Tipton.

If you require prototypes for specific projects, development samples, plastic tubes in custom sizes, Naylor Specialist Plastics Ltd. can provide exactly what you are looking for.

If you would like to discuss your requirements in more detail, why not contact us so we can help you to find the right solution for your project?

More than 130 years’ experience

Although Naylor Specialist Plastics Ltd. is a relative newcomer to our group, our history goes all the way back to 1890.

Founded by the great grandfather of our current CEO, Edward Naylor, you can be confident in our manufacturing history, supply experience, industry expertise, and supplier reputation across a number of different sectors.

This solid foundation has enabled the Naylor Group to invest, expand and diversify in order to service emerging industry sectors and to stay one step ahead of ever-changing industry requirements and regulations. You can read more about the history of the Naylor Group on our website.

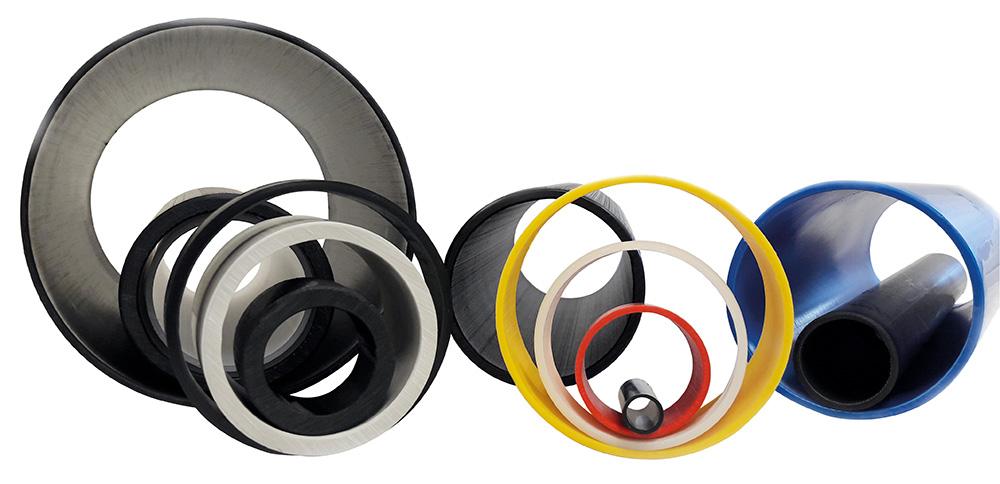

Bespoke Plastic Tubes

We want to ensure that our bespoke service will address every customer requirement, no matter the sector.

We have the manufacturing capability to produce bespoke tube products for our customers, whether the requirement is for development samples, uncommon sizes or short production runs.

Put simply, if it is tubular and made from plastic, you can be confident that we can make it!

We are committed to continuous improvement so we can provide our customers with innovative bespoke products, designed specifically for individual projects.

Any size of plastic tube can be manufactured, from 2mm all the way up to 315mm, with a wall thickness ranging from as little as 1mm up to 20mm.

With comprehensive tooling support and large stocks of raw materials, we can ensure lead times are kept to a minimum.

We can provide bespoke plastic tubular products for a range of different application across many industries including:

- Geotechnical survey tubes

- Tubes for use in food contact applications and equipment (FDA approved)

- Tubes for water irrigation systems

- Plastic ducting

We also have the ability to manufacture prototypes for specific requirements thanks to our inhouse tool-making capabilities.

You can be sure that whatever the project, Naylor Specialist Plastics Ltd. has both the manufacturing expertise and industry knowledge to produce bespoke plastic tube products designed to your exact requirements.

Bespoke plastic profiles

In response to the demand from a variety of industries for flexible extruded product, we have continued to invest in state-of-the-art equipment and machinery in our 28,000 square feet manufacturing facility.

Our bespoke plastic extrusions and profiles are manufactured to your exact specification in all aspects: material, dimensions, and colour.

We can make product up to 315mm diameter in various grades of material, depending on the application and industry requirements, from 24 lines featuring new extruders and spiral mandrel die heads in our Tipton and Wombwell manufacturing plants.

Stringent product testing

Untested or uncertified products may not offer the performance level required, and when issues become apparent, it may be expensive to put them right.

During 2021, we tested a total of 2,300 batches of product and across the Naylor Group.

The testing protocols for specialist plastic products are set by individual customers according to the application and project while those with third party certification are often tested above and beyond the minimum requirements set by the external body.

We want our customers to have confidence that when they buy specialist plastic products from us, that they adhere to the highest standards.

We show our commitment to product quality through our compliance team, employing eight full-time compliance and quality assurance professionals, along with a Quality Engineer for each site.

Continually moving forwards

At Naylor Specialist Plastics Ltd., we continually move forward in order to meet the requirements of our customers thanks to our overall vision and ethos encompassing:

- Relentless innovation

- Continued investment in the latest equipment

- Expansion via an organic growth and acquisition philosophy

- The motivation, training and development of our employees

- A willingness to listen to innovative ideas from every part of our workforce

Last year, we expanded through the acquisition of D&B Injection Moulders to complement our electrical conduit manufacture, enabling us to offer an enhanced range of products within the electrical contracting and distribution industries.

Our manufacturing capacity has increased tenfold during the last few years thanks to ongoing investment in new equipment.

Our latest investment has been a new 160mm spiral mandrel die head to go on to a new 75mm extruder.

This is the last extruder and tooling to be commissioned in our Tipton facility, resulting in 11 lines with new extruders and spiral mandrel die heads.

In addition, we will be upgrading downstream equipment this year so we can continue to increase the volume of extruded product we are able to manufacture.

We are focused on expanding our product offering and optimising manufacturing efficiencies so we can meet customer demands in the future.

Our commitment to product innovation and development saw us invest an average of £750k per annum into R&D during the last five years (up to 2022.)

If you have a requirement for bespoke plastic tubes and would like to find out how Naylor Specialist Plastics Ltd. can help, contact our team of experts to discuss your project in detail. We are confident that together we can find the perfect solution.